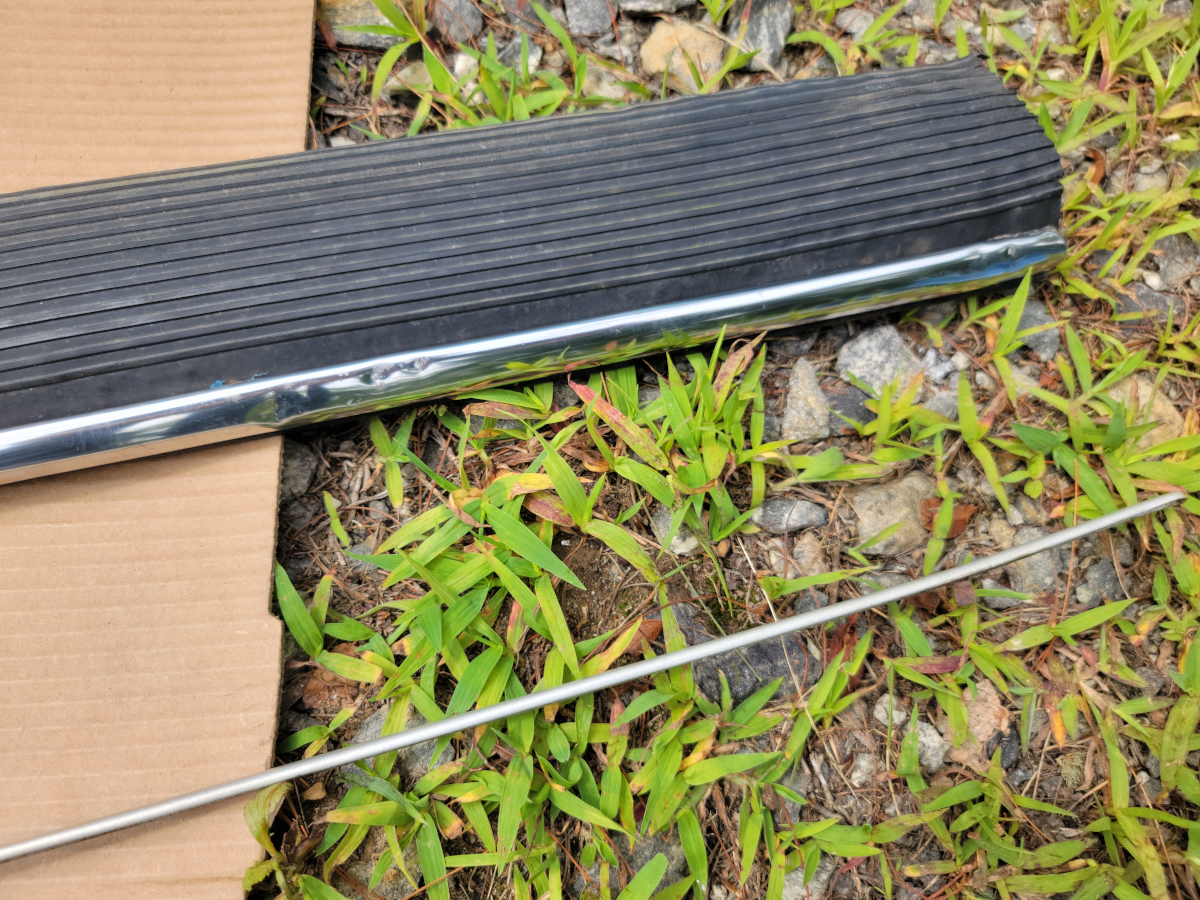

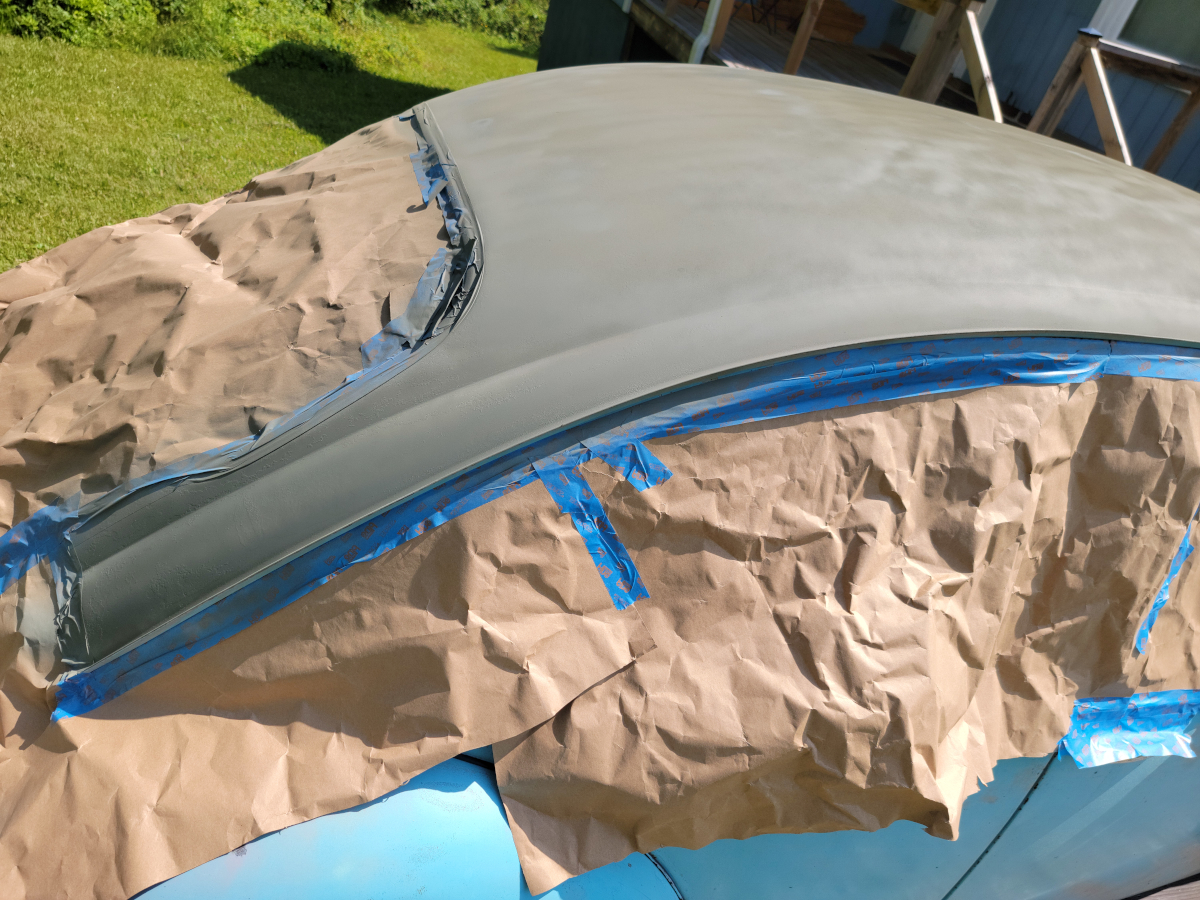

When preparing my Ranger to go up for sale, I noticed the wiper arms looked really shoddy. Paint faded and chipped and surface rust. The ones on the Beetle had previously been painted but were also looking pretty shabby. I decided to take them all off, clean them up, and paint them.

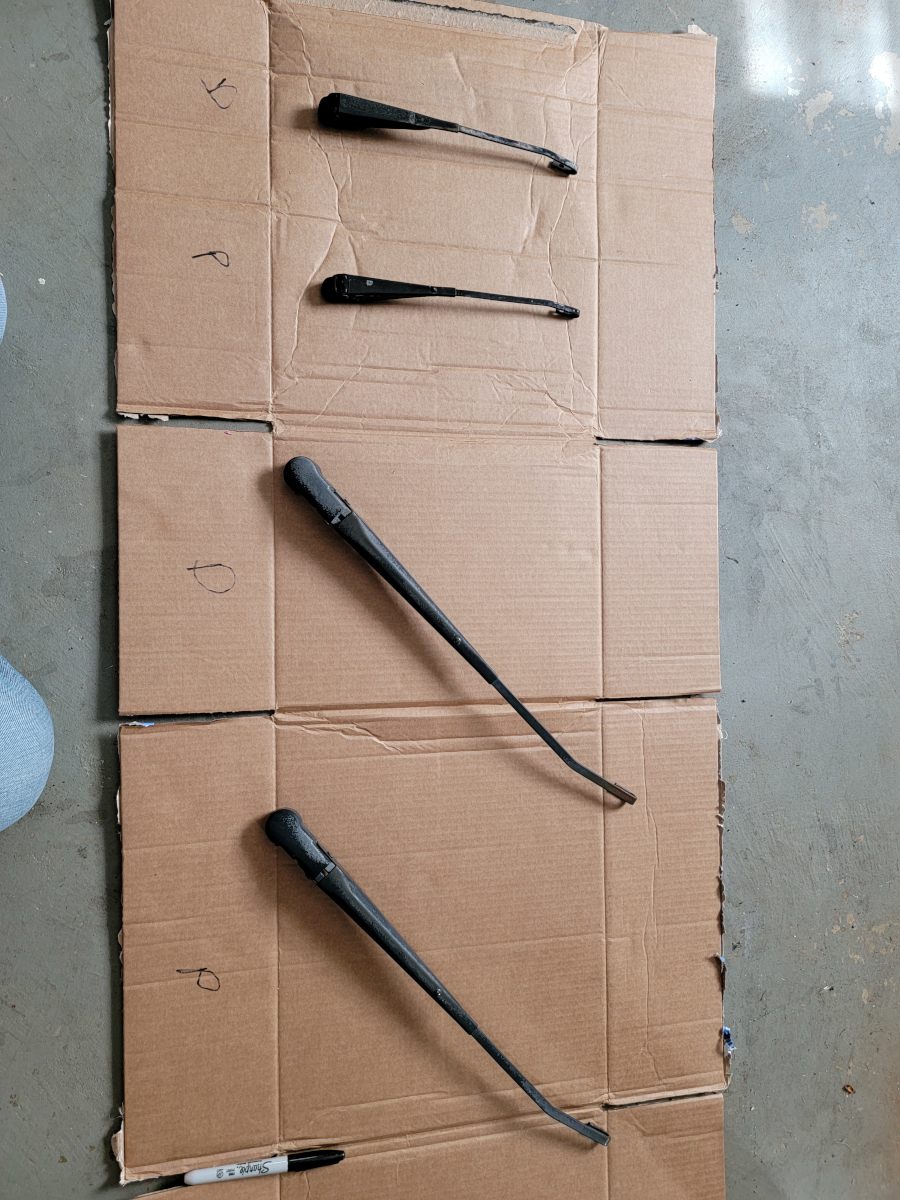

The wiper arms appear to be interchangeable on the Beetle, but they are different. Likely one was just replaced from a different year. The Ranger appears to have identical left and right arms. I kept them all separated and labeled just in case.

Wiper blades off…

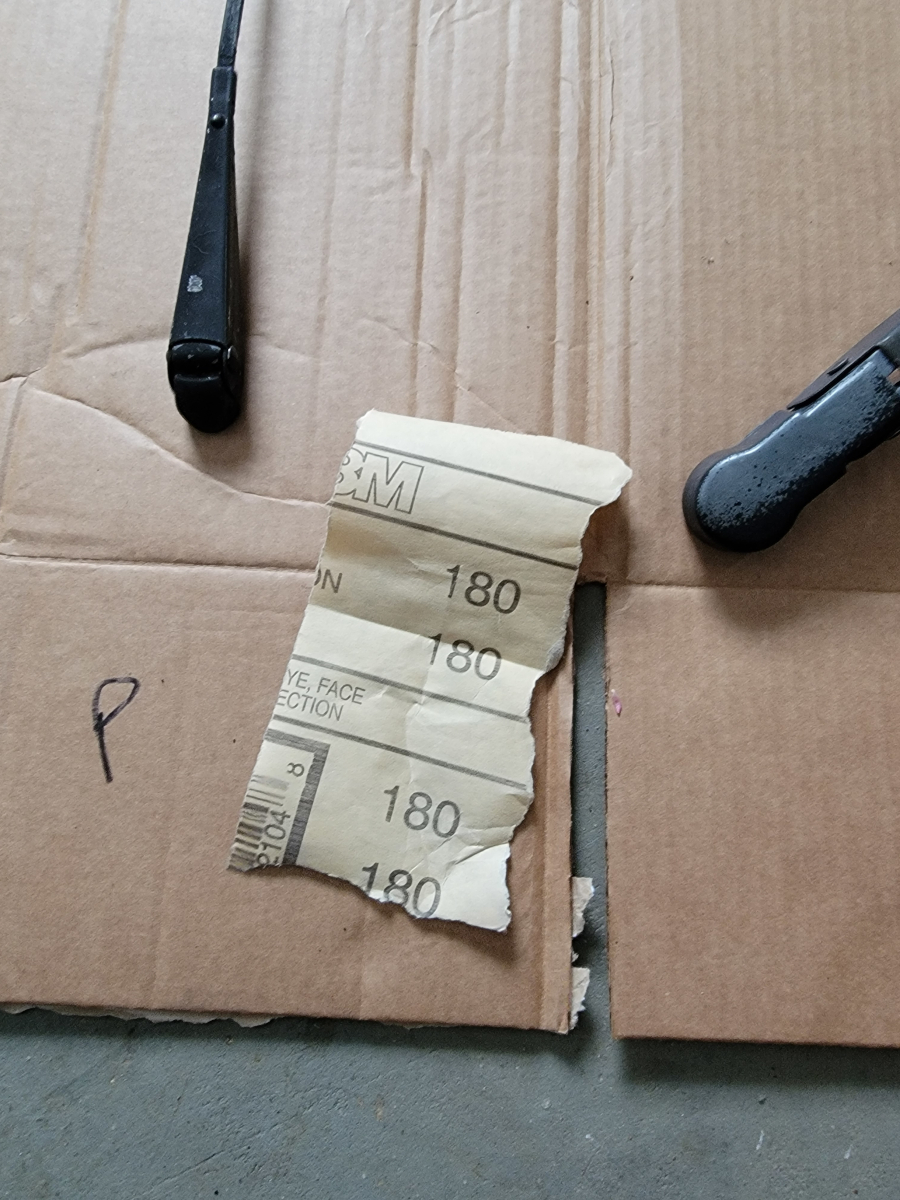

…and hit them with a scrap of 180 grit sandpaper I had laying around.

It smoothed the rough paint edges and left a nice scuff for the new paint to stick to.

I wiped them down with acetone to get rid of dust, dirt, and oils.

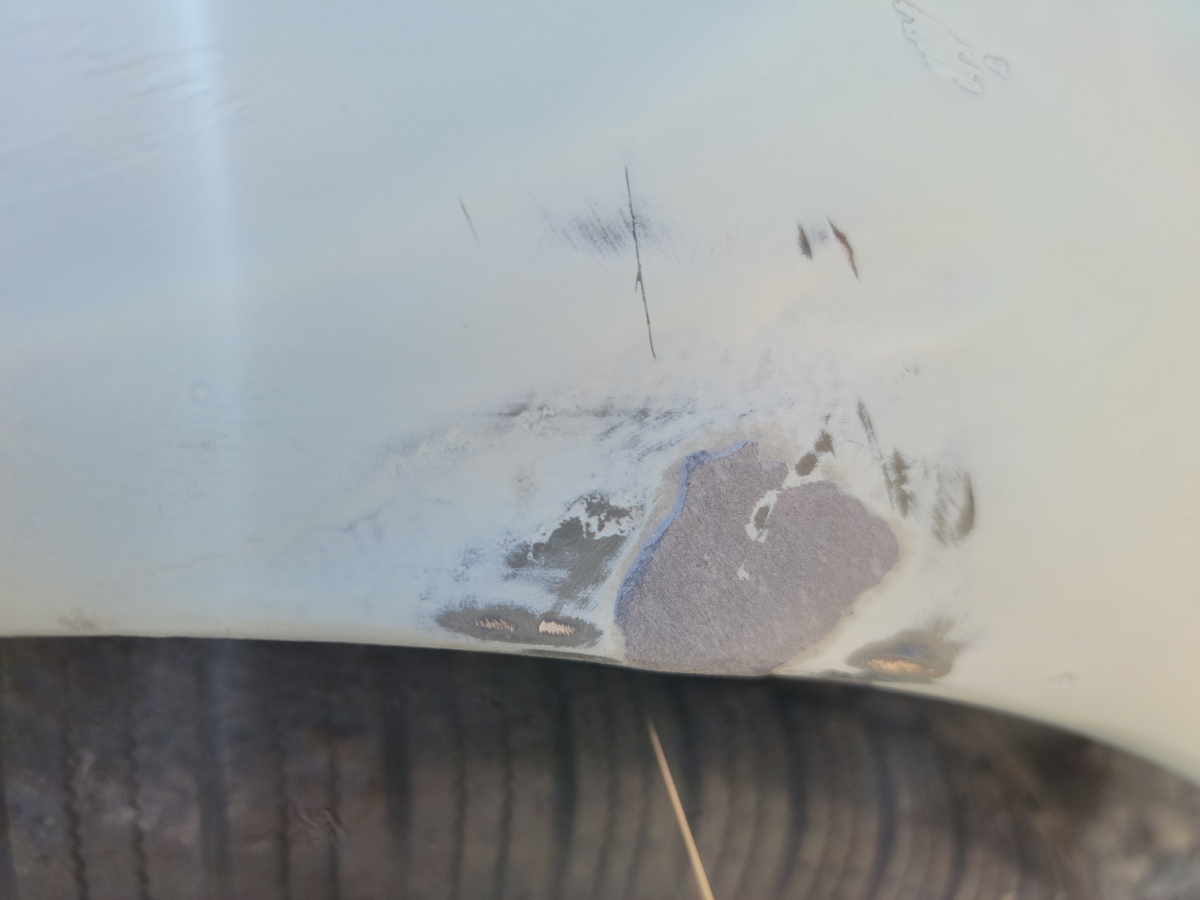

And gave them a coat of Dupli-Color Rust Barrier.

And then a couple of coats of Dupli-Color DE1634.

The wipers don’t work very well in the Beetle, like they don’t have enough tension against the window to actually clear anything. I wanted to check the springs, to see if I could cut and stretch them or find beefier replacements.

As soon as I gripped it with needle nose pliers, the rusty spring snapped. So, it was time to put the wipers back on the Ranger and go parts shopping.

Nice.

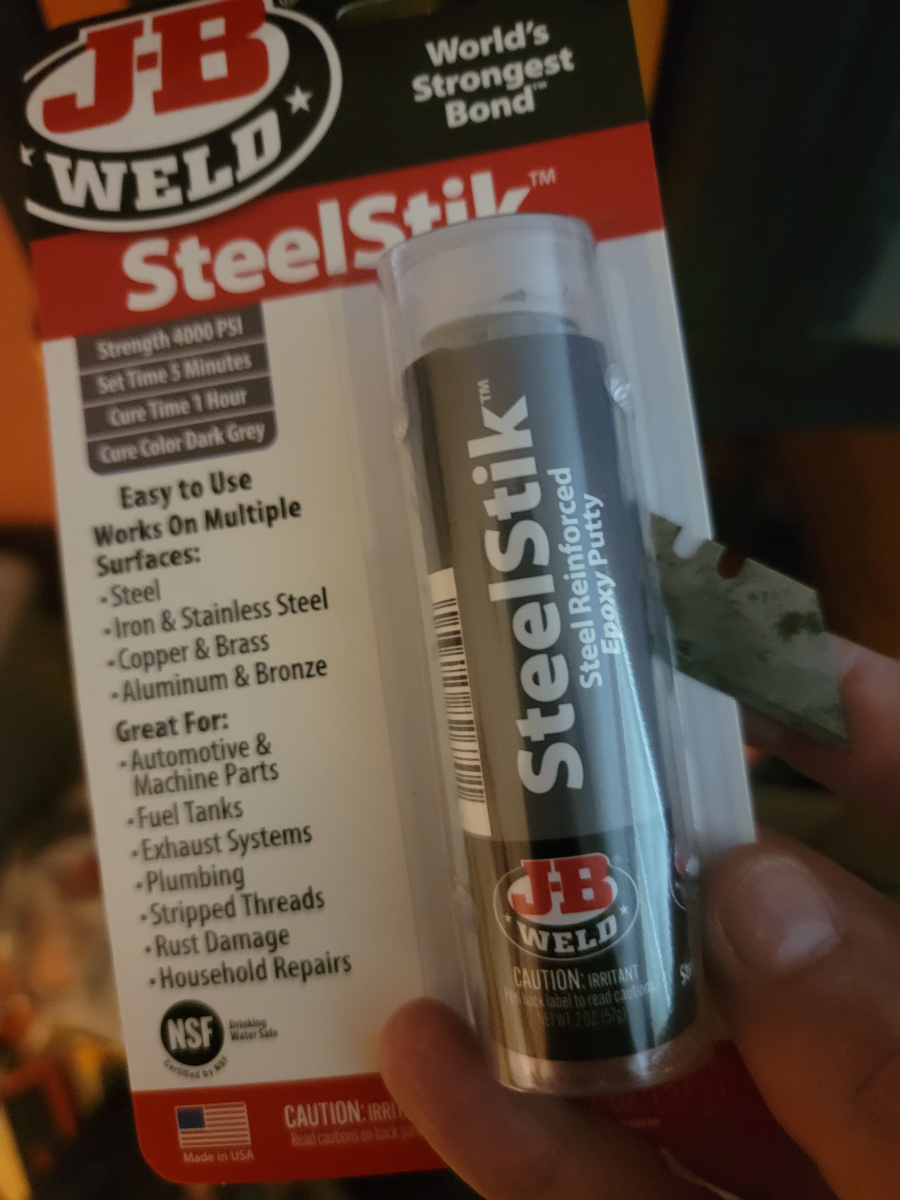

I went first to O’Reilly, figuring they would have that type of thing in the hardware aisle, but they only had bigger sizes, like throttle return springs.

There’s an Ace Hardware next door that usually has better hardware than parts stores and even big places like Lowes and Home Depot.

I found a close match here. The spring is a little smaller diameter and a little longer, so I figured I would have to do some surgery.

I didn’t take that picture specifically to post here. They didn’t have any writing implements in the hardware aisle to note the item number or price on the bag.

That’s the first time I have purchased something with cash in quite a while. I try not to stick retailers with equal amounts of credit card processing fees and purchase price.

They mounted back up without issue and look nice. They kind of disappear into the windshield trim, as it should be.