I’m about to replace the parking brake cable on the driver side, but I started off the day by reinstalling the missing knobs in the dash.

I have purchased two new wiper/washer knob sets and neither have fit correctly. The existing one has a tendency to spin on the threads when you turn the wipers on, making it difficult to turn them back off. Also, visually, the print is worn off the washer button. So, here we are, with the old button and knob mounted again.

Now, moving onto that parking brake cable. As mentioned in a previous post, the driver’s side cable adjustment was screwed down all the way and the brake was barely grabbing back there. I had the new cable on hand, so let’s dig in.

I peeled back the new rubber cover I had put on earlier and removed the double nuts.

Then I got the rear wheel up in the air and removed the cable mounting plate from the back side of the brake assembly.

It took a lot of finagling the cable ends and moving back and forth between the driver’s seat and the rear wheel, but eventually, I was able to get the old cable out. It was covered in thick, black axle grease, so that’s good.

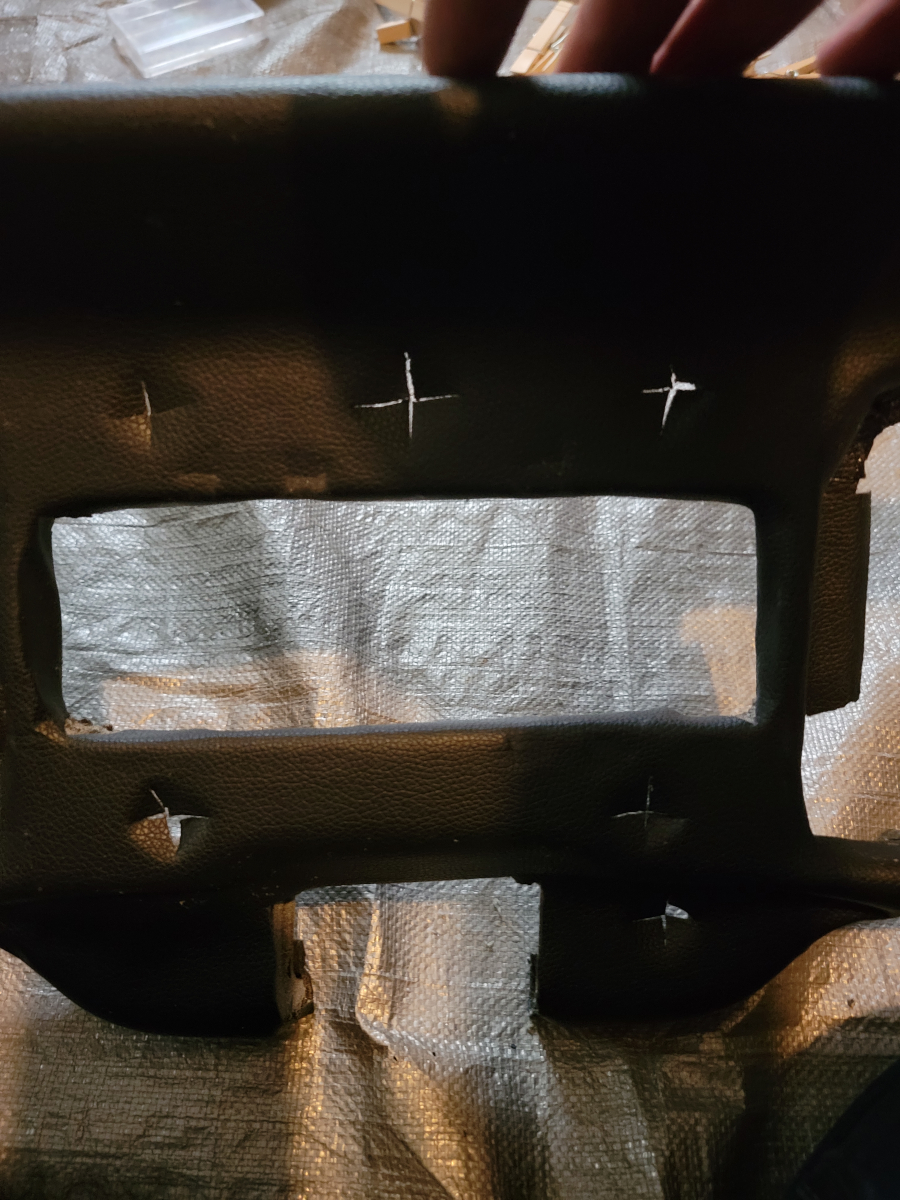

Once I got the new cable slathered up with axle grease and fed back through to the front, it took a lot of wrangling to actually get it pulled up through from the tunnel. By the time I snapped the next picture, I had removed both front seats and the parking brake handle assembly. That made it a lot easier to get into place.

Time for a break. BEER ME.

OK, back at it.

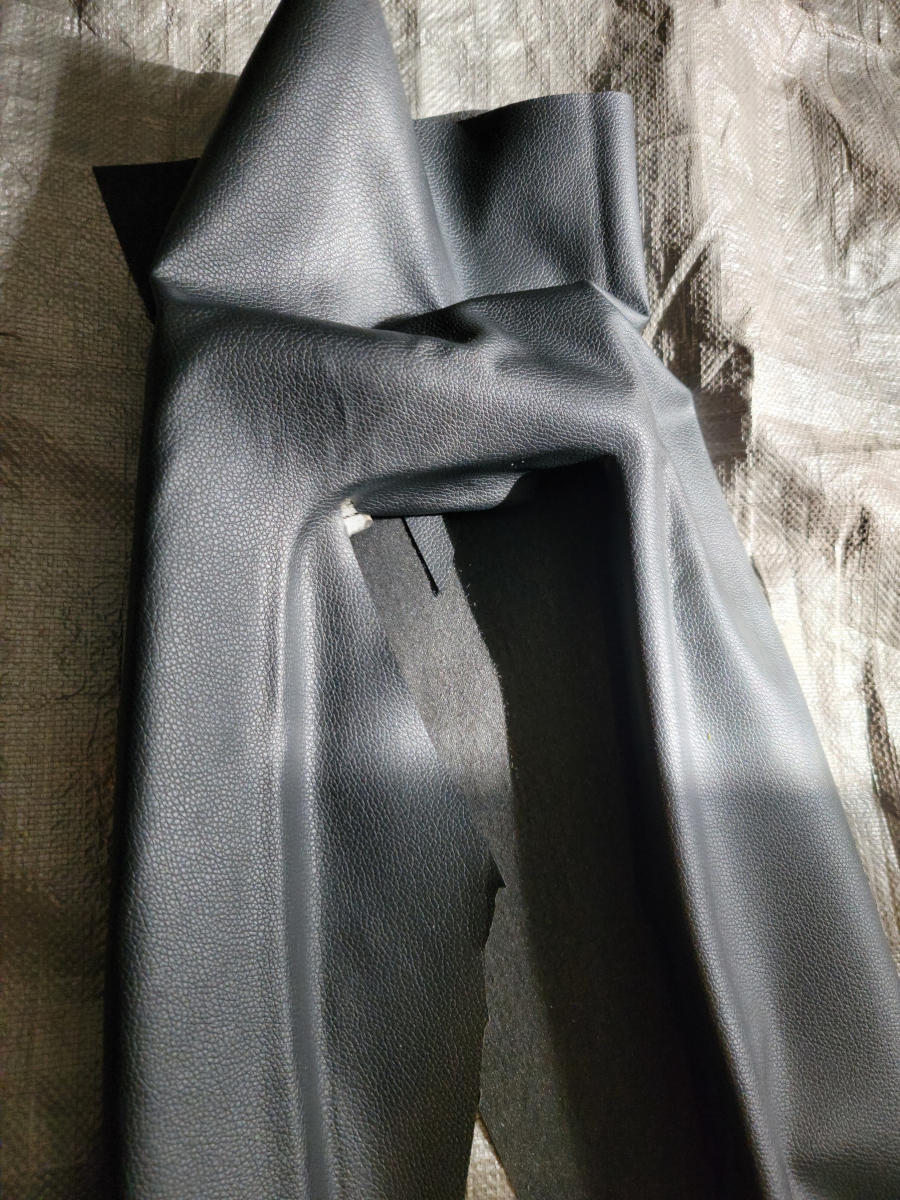

The new cable I bought already had a crack in the black plastic sleeve. The parts aftermarket manufacturers and sellers should seriously be ashamed of themselves. I have never consistently bought so much garbage in my life.

After getting the wheel mounted and brake adjusted, I was then able to get the cable adjusted. I want to not be able to turn the wheel by hand with the parking brake handle about 3/4 of the way up. The cables will eventually stretch and brake shoes wear, so it’s good to have some room left to adjust the cable tighter as needed.

And now the rubber cover is back in place and not stretched over a hot spot of that long cable end.