A couple of months ago, I purchased new brake drums all around. More than one of the existing drums are out of round and the front right tends to grab the pad at really unexpected times, trying to pull the car off the road.

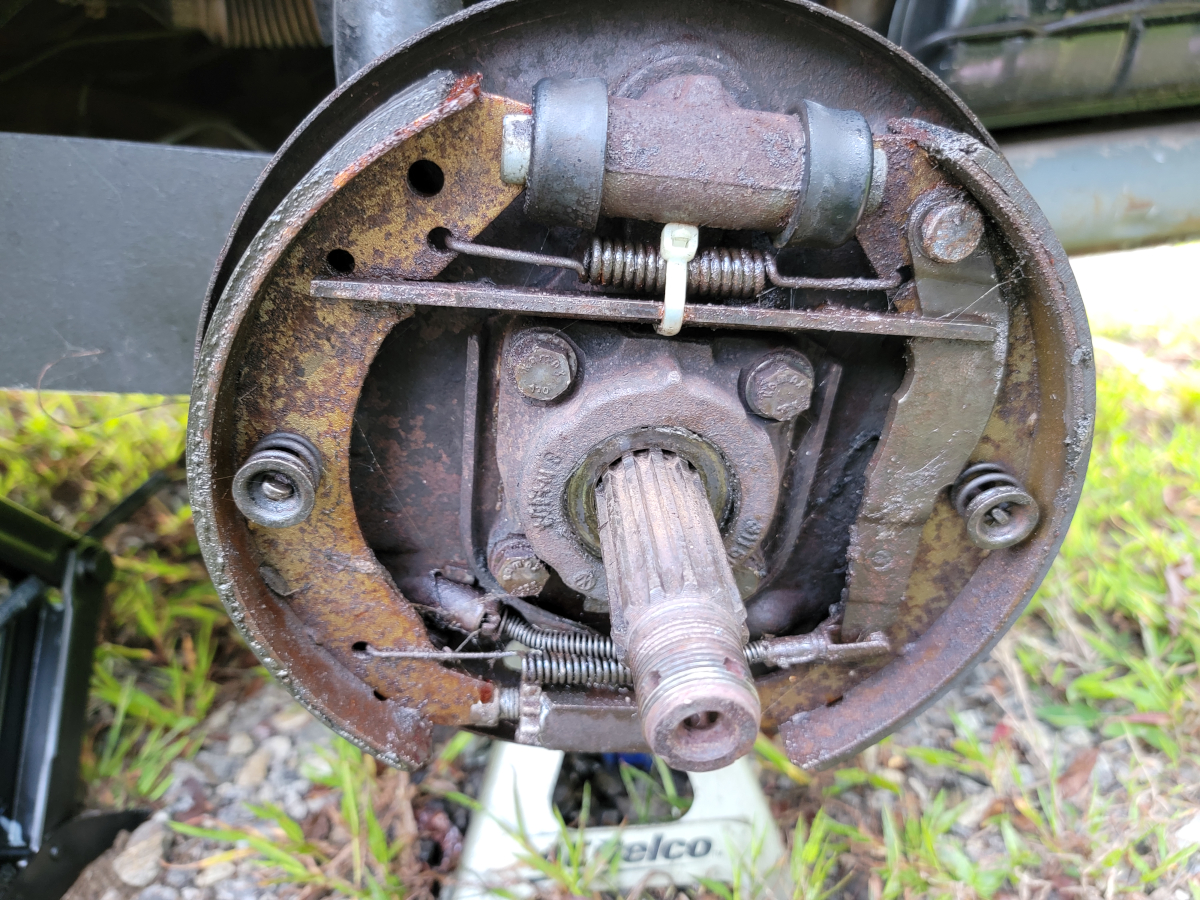

After jacking up the rear driver side wheel, I pulled the old brake drum off.

Things are dry, which is good, but a little rusty.

After hosing everything down with brake parts cleaner and wiping down the new brake drum, I realized I had grabbed one of the new front brake drums. The part pictured above, 365-74004 is the rear drum.

These star adjuster wheels were both frozen/stuck. I spent a long time trying to get them freed up, spraying PB Blaster several times, before giving up. Finally, I just took the bottom spring off and was then able to pull the bottom ears of the brake shoes out of the adjuster ends. Then I used a large flat screwdriver to turn the adjuster bolts manually.

Eventually, I got a nice, snug fit of the new drum over the shoes and buttoned it all back up. I forgot to take a picture before I got the wheel back on.

You can kind of see a bit of it in there. It’s painted black and surprisingly, the brake parts cleaner didn’t seem to wipe the paint off, so that’s good.

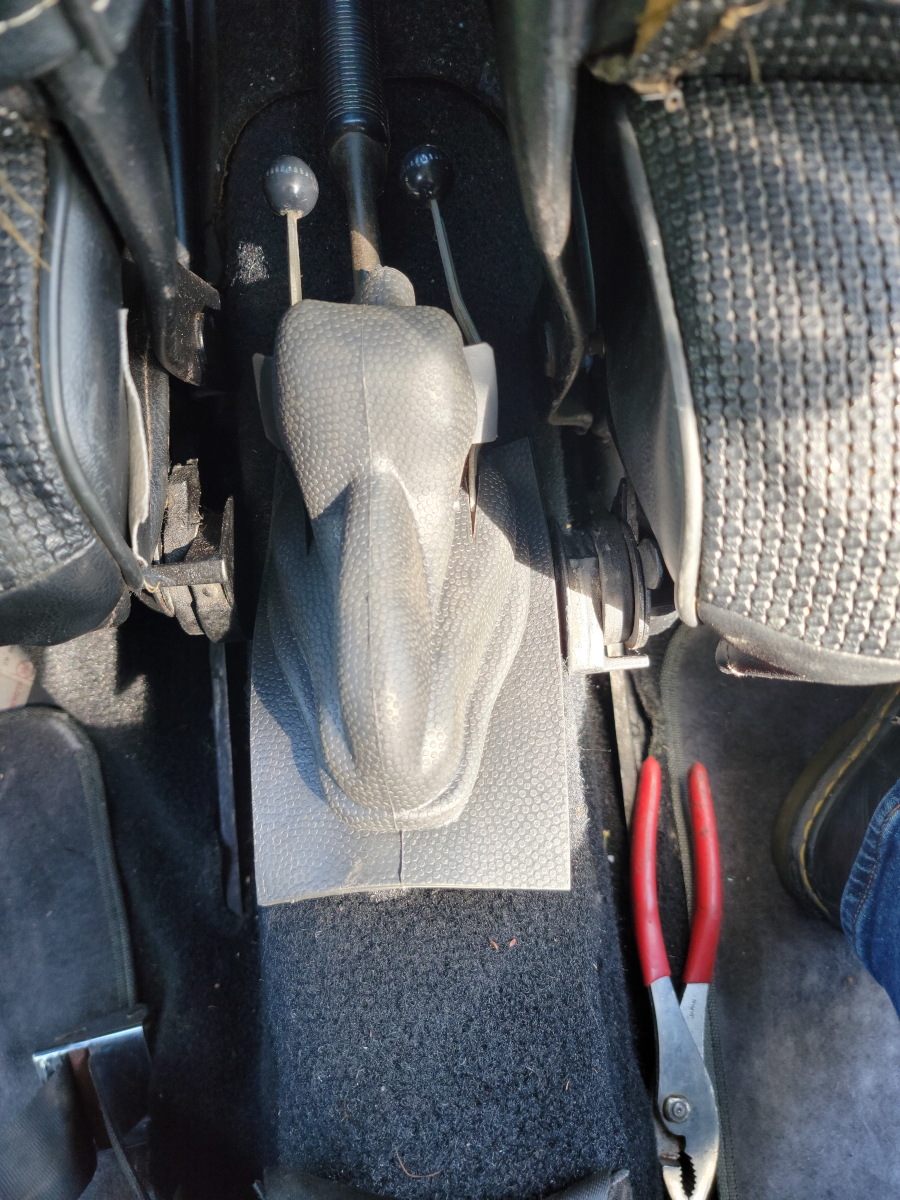

Apparently, I gave up on documenting the process completely at this point, as the only other picture I took was once I finished up and was packing things away.

Unfortunately, I found that the passenger side rear drum was wet inside – black. Goopy and black. I wondered if the new brake cylinder I replaced last year was leaking again, but it doesn’t appear to be the case. The brake fluid reservoir is still completely tip-topped up.

Is it possible that transaxle oil is traveling down the axle?

I put the parking brake on full, put the car in neutral, and wasn’t able to push it. The brakes appear to be tight. I will take the car out for a runaround later today.