After replacing the brake master cylinder with a Dorman model, I noticed the brakes were already fading by the end of the 150 mile trip home. I started the trip with a full, hard brake pedal. By the time I got home, there was barely any braking down to the last inch of pedal throw. The last couple of times I have driven the car, the brake pedal was clacking against the floorboard. I have always kept an eye on the back side of the wheels, looking for leaking wheel cylinders, and up to this point, they were always dry.

So, I ordered a new master cylinder, this time a NAMCCO model (Amazon link). When installation day came, I jacked up the front of the car, removed the drivers side front wheel and there it was, rusty new master cylinder. Brake fluid was leaking from the hard line at the front and the rubber inlet.

When I got everything disconnected, I found the top hose that we recycled should probably not have been.

It wasn’t losing much (if any) brake fluid, but I think the pressure was escaping without creating puddles. I cut that nasty end off and recycled that hose again. Lesson definitely not learned.

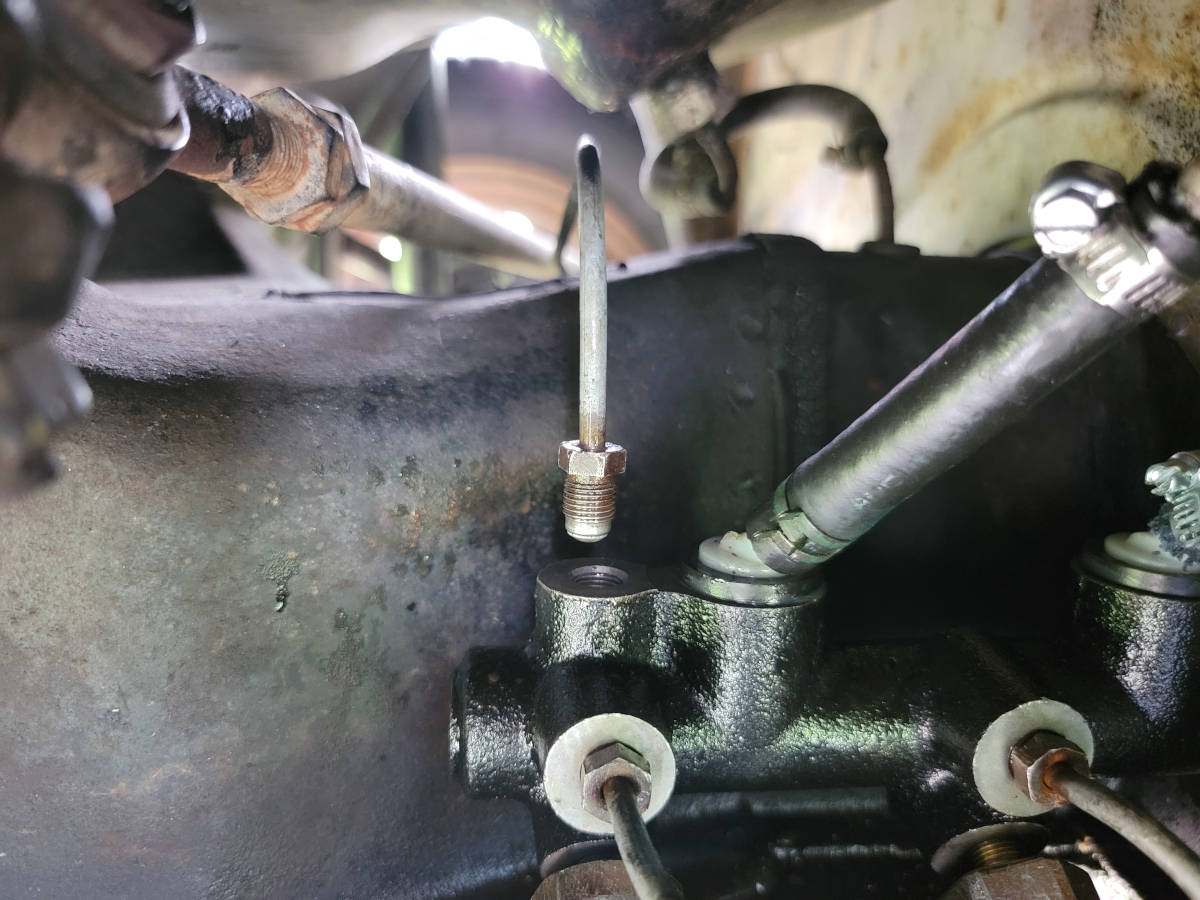

I got the new master cylinder mounted to the firewall, to keep it from flopping around while trying to connect those hard lines and the inlet hoses.

I got everything reconnected except the very last hard line. I was maybe 45 minutes into the process at this point, then spent the next hour or more trying to get it started.

With my fingertips raw and fully defeated, I packed it up for the day.

Convinced that I couldn’t have been doing anything wrong, I decided the master cylinder must be drilled or threaded wrong. I got the old master cylinder out and the hard line screwed right in without issue.

I have been looking for a reason to buy a tap and die set for a long time.

With this being a strange size and thread pitch, I had to get a complete set (Amazon link), or pay nearly half as much for just that one size.

Anyway, in talking to my dad about it, he said “If you unbolt the master cylinder from the firewall, I’m certain it will thread right in.” He was right. Mostly. It was still tough to get it going, but after a tough half a turn, it broke through and threaded the rest of the way in, instead of popping out like it was before.

OK, so, that worked great. I took my manual brake bleeder vacuum gun around, bled each wheel, and had a good, solid pedal. Maybe not as much as last time we changed it, but good, safe transportation.

One win and one loss. Randomly, the drivers side headlight was cracked. I’m sure that is a result of the previous struggles I had with even getting the trim rings to mount at all.