As mentioned in the Panel Beater post, my last batch of shine juice clotted up and became tacky cement on the car. It wouldn’t wash off. Mineral spirits wouldn’t take it off. I ended up wiping the whole car down with Acetone, which accomplished a couple of things.

It easily cleaned off the shine juice residue, but also removed the top layer of dead paint. Since I have been washing the car with Scotch-Brite pads and CLR, it didn’t break my heart that more of the light blue paint was coming off.

What did break my heart was seeing that the sun-burnt rust spots on the roof were much more deeply pitted than I had previously noticed. I felt like I needed to take action beyond keeping it oiled up with shine juice to try and slow that rust down. Having ten cans of that Matte Vintage Blue spray paint sitting around didn’t help to deter me from the bad ideas that were creeping up.

I got a can of Sprayway glass cleaner, a sanding block and some 220 grit wet/dry sandpaper and went to work.

After getting it smoothed out for the most part and fading up the edges of remaining blue paint, I got it all washed and wiped down with another several rounds of Sprayway.

A few places had bare metal peeking through, but for the most part, it was down to rust and factory paint.

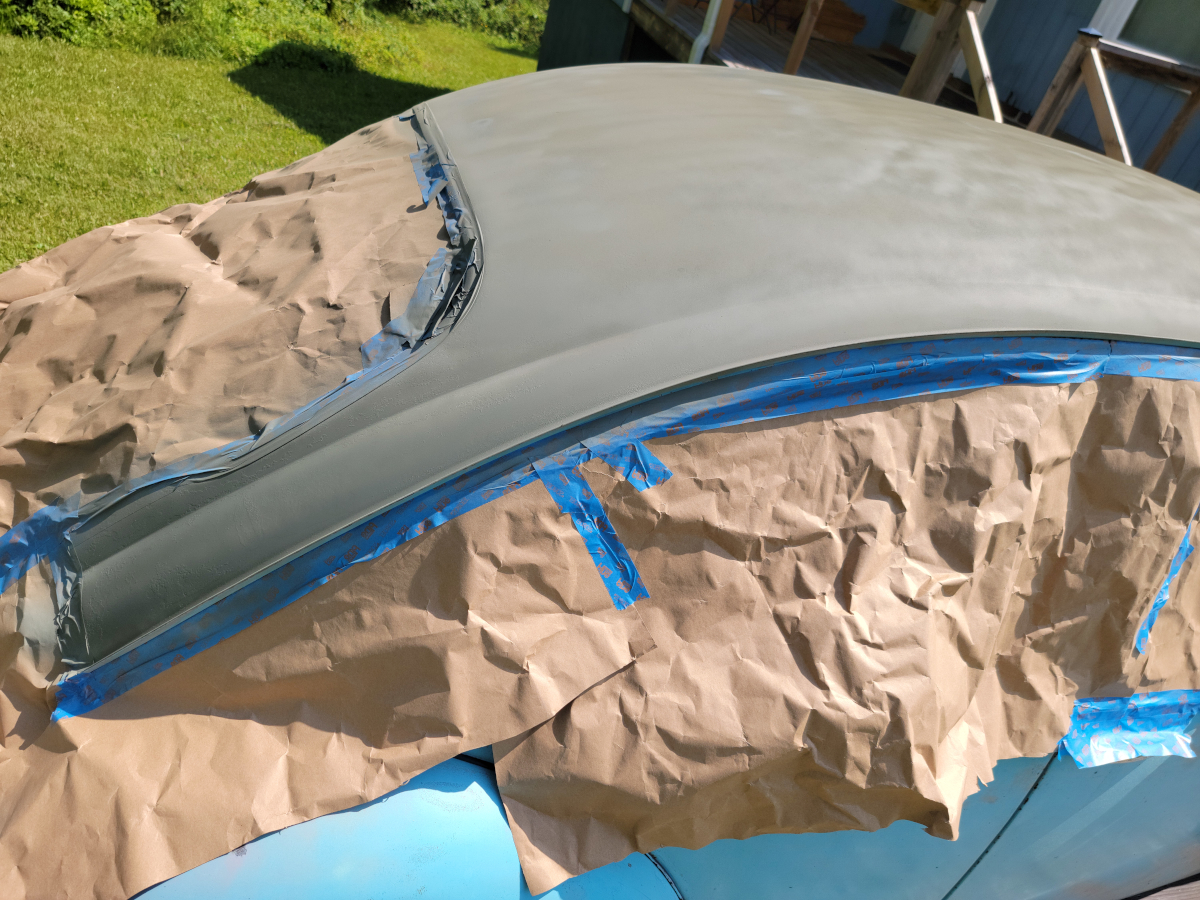

I had some brown packing/craft paper laying around from various parts shipments and decided that would be good enough for masking the windows.

I started off with two or three coats of rust converter spray.

And then two coats of primer.

It was still early in the day, like 11:30AM, but the sun was out and the primer seemed to be drying in the air in between the can and the car body. There was a ton of over-spray. I got (what I thought would be) a lint-free cloth to wipe it down in between coats…

…but clearly that just made a mess. I went back inside and found a microfiber rag that did a great job cleaning the lint and dust off. The primer was still really textured, though and I wasn’t sure about the amount of time needed for that to properly set up, to withstand another wet sanding.

I put a thin coat of color on next.

And then another.

By this time, it was after 5:00PM and I didn’t want fresh paint getting wet overnight, so I decided to stop here.

After removing the masking: