I previously fixed the passenger side rear brake and got it adjusted. Now it’s time for me to check the driver side.

One could wonder why the parking brake wasn’t working… I found when clipping the end of the cable back in place, there was a lot of slop and I could imagine in normal use, it could work its way off. When I was recently reviewing old posts here, I noticed when I first looked at the parking brake cables, the driver side cable was tightened down as far as it would go. Maybe this is why.

So, I clipped it back together and re-adjusted the brakes. Tightening that cable all the way back down and applying the parking brake would almost stop the wheel from turning (by hand).

Note to self: The driver side cable is the one that needs to be replaced. Now I know it is just stretched, not broken.

Then I took the passenger side wheel off again and re-adjusted the brakes.

I then tightened the passenger side cable to where I couldn’t turn the wheel by hand with the parking brake lever about 3/4 of the way up. The rear passenger side wheel is now rock solid when the parking brake is on.

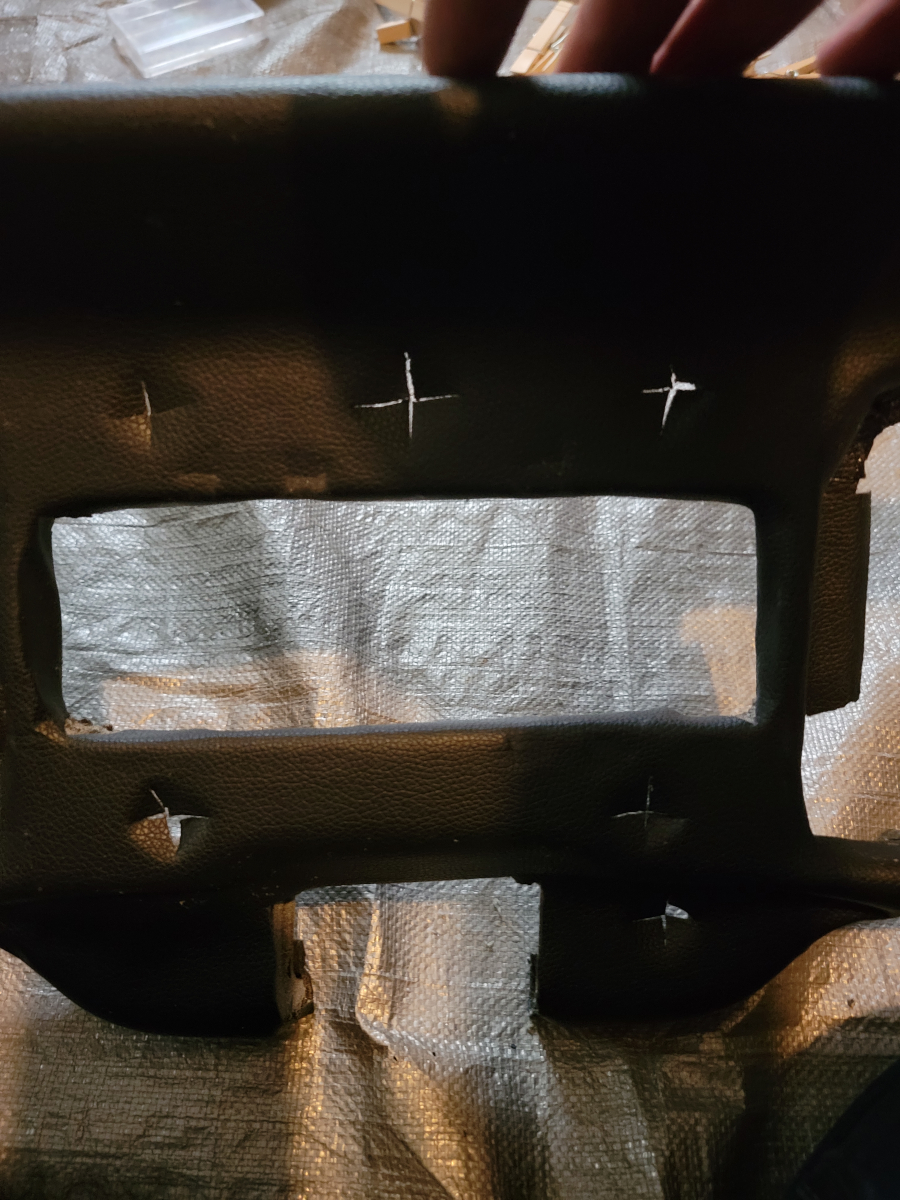

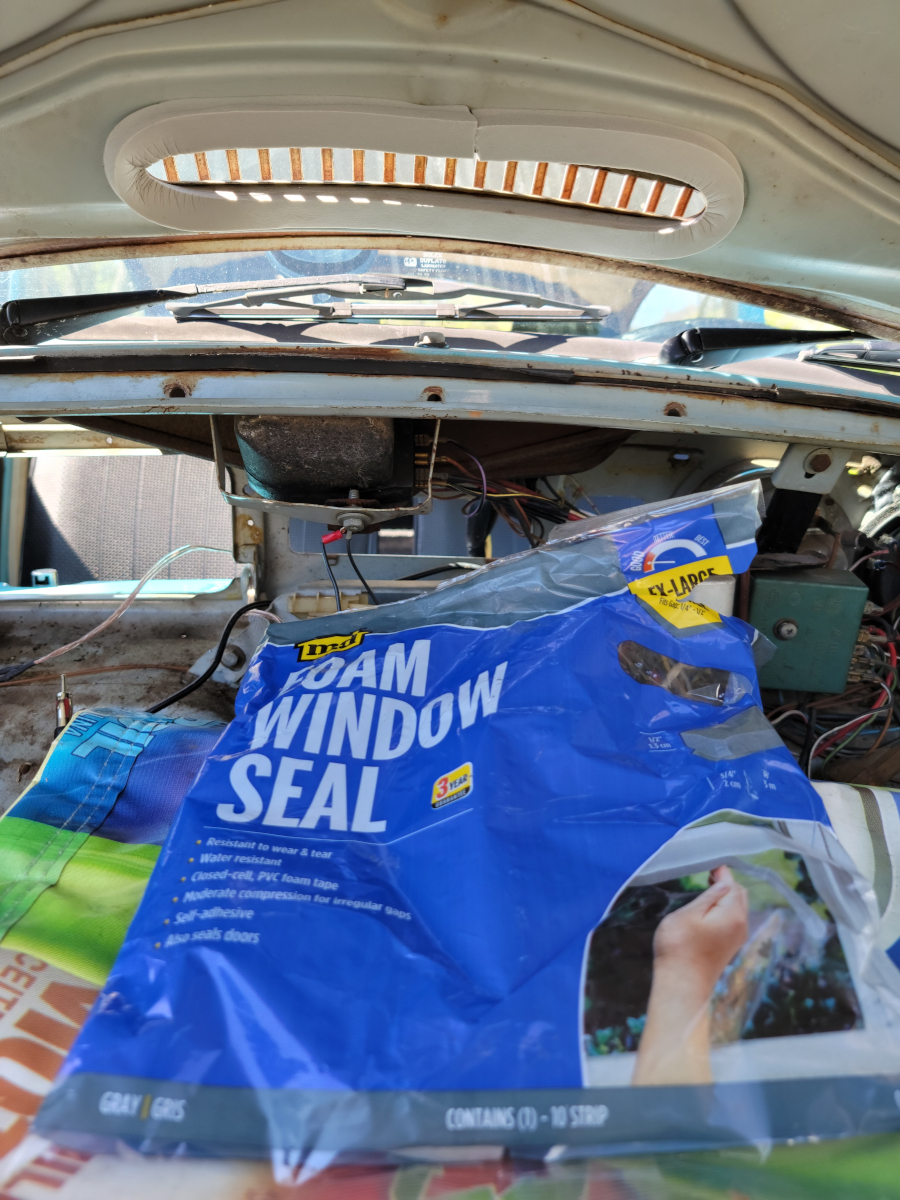

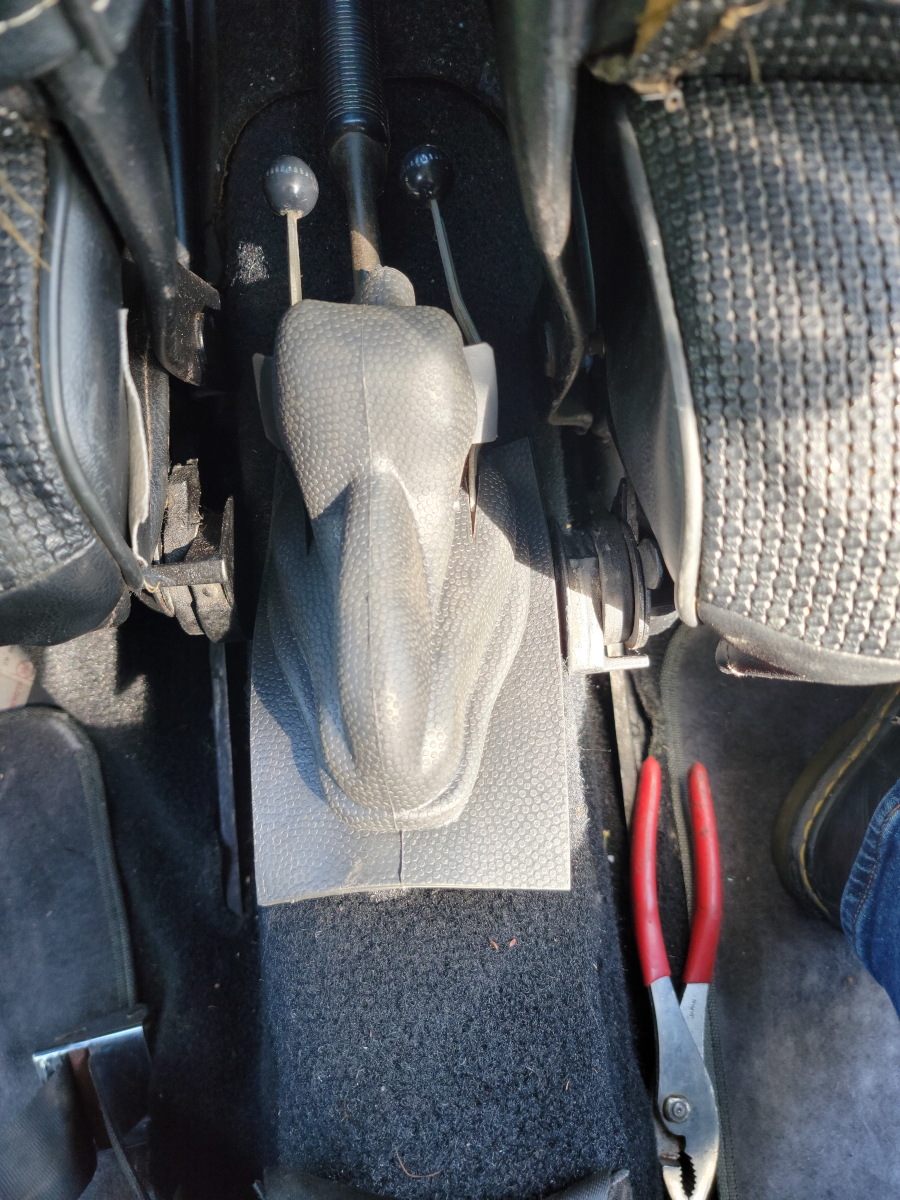

I remembered that I had purchased a new dust boot cover for the parking brake assembly. Now that the parking brake is working again, this is the perfect time to install the new boot.

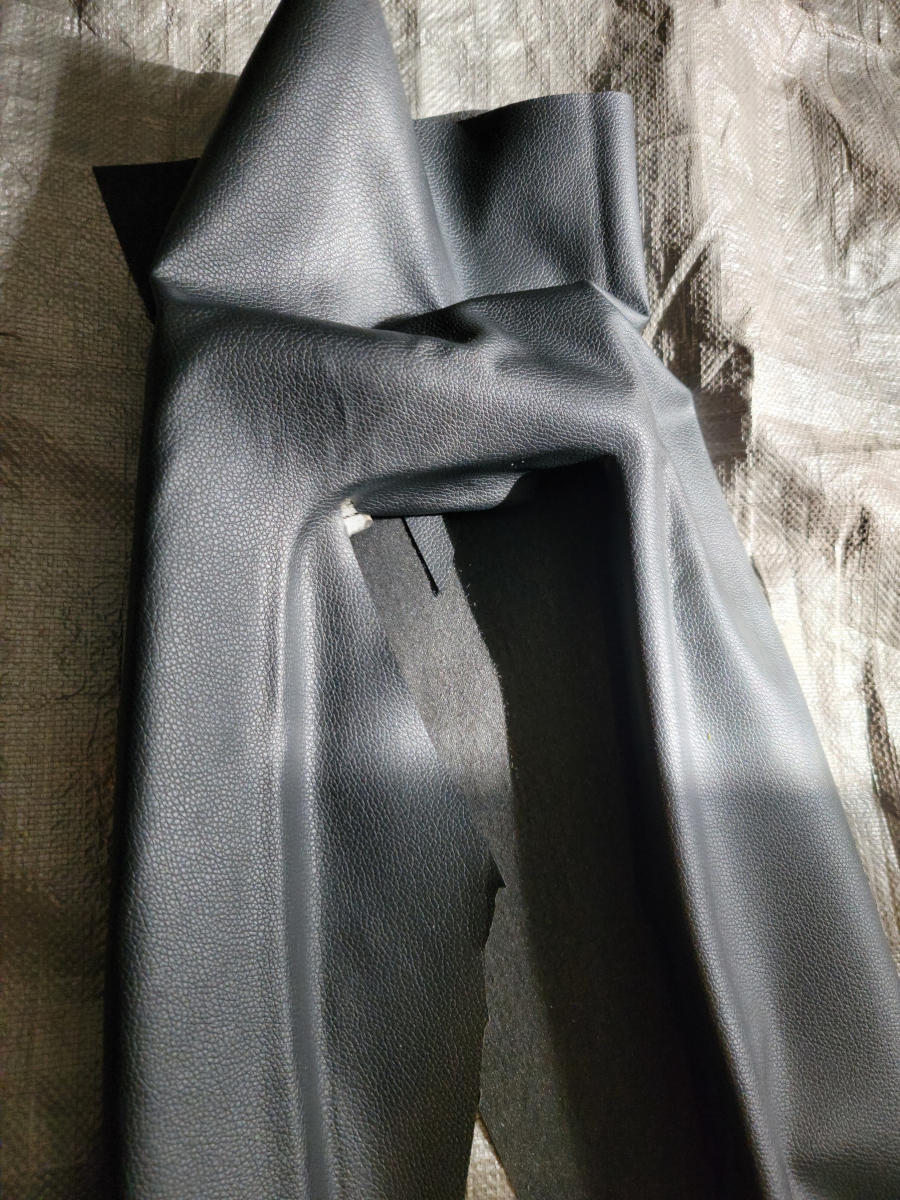

It’s a big stretch and not a comfortable fit. With the heater vent levers pulled through, there was just no flex or stretch to be had.

Let’s move into the back seat for better leverage.

From there, I was finally able to stretch the boot into place.

I had to put in some effort to get the carpet stretched back enough to allow all that excess rubber to be hidden below.

But, I eventually got it. You can see in the pic above, that extra long parking brake cable trying to push through the top of the dust boot.

Now, I can run, stop, and check my mail at the top of the driveway when I get home. The parking brake is essential in the mountains.

This was a much needed win.