It’s day 2 of the driver’s side front seat rebuild.

Patching the vinyl seat covers

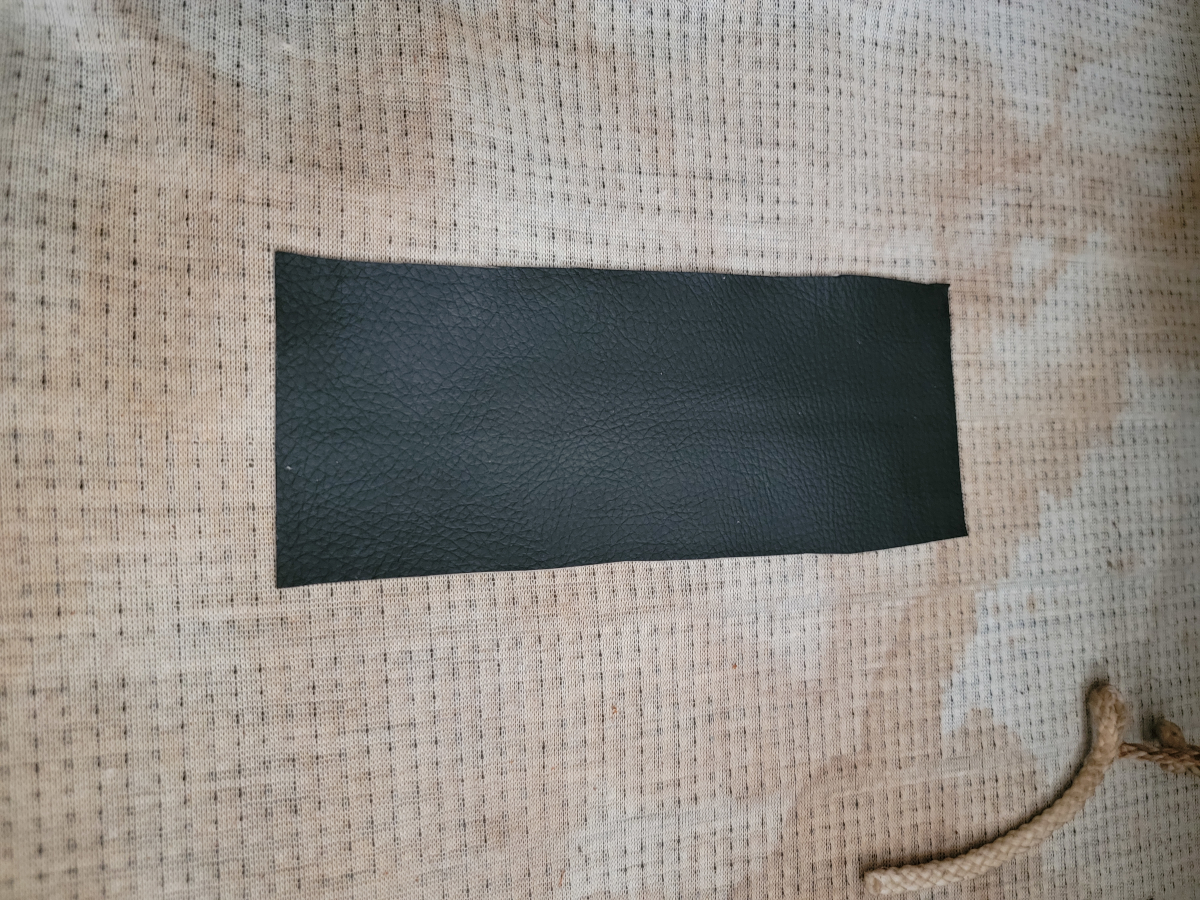

Once the roll of vinyl repair stuff (Amazon link) arrived, I got started patching up the seat covers. I picked up some Gorilla Clear Grip (Amazon link). The package says to use it like E6000, so I did.

In places where there were gaping holes in the seat cover, I used the vinyl patch as a backing and glued it with the glue. Where that didn’t look great from the outside, I just slapped a patch on the outside and used the adhesive backing on the vinyl repair roll.

Replacing the seat foam

I had previously picked up some low density green upholstery foam pads (Wal-Mart link) and decided to use those in the seat backs. After cutting a seat pad and seat back out of the high density foam roll I bought, I realized there wasn’t going to be enough for both front seats.

It was a really tight fit in the seat back and needed to be massaged into place. The seat back cover started off being 2-3 inches away from being able to snap closed.

I apologize for the gratuitous crotch shot, but luckily, I’m still a baggy pants 90s kid, so it could have been worse.

We don’t need no rusty snaps

I pulled the plastic side bar supports out to free up some space and was finally able to get the ends to meet up, but the snap was failing. After bending the female side of the snap into a little oblong, it finally held.

I did the same with the other side and got it snapped as well.

The middle snap had been previously pulled through the vinyl, so I cinched it all together with zip-ties.

I then got the side of the seat back wrestled into place to be able to put the plastic trim piece and knob for the seat back release lever in place.

Once the seat back was fitted, I wriggled those plastic side bar supports back into place. The fit is now very revealing. As you can see in the picture above, much like Robert Plant’s hip-huggers, you can see the hog rings that are holding the jute webbing in place.

Moving on to the seat base, it was a much better fit than the seat back, initially at least. With all the stretching and pulling, the strings sewn into the front edge of the seat cover snapped off. They were very crispy. A zip-tie helped cinch it down.

One edge at a time, I stretched the cover down over the bottom of the seat base and stabbed the little prongs through. The last edge was the toughest, as you might imagine, but smooshing the seat springs down with one hand while pulling with the other was enough to bring it home.

Buttoning it up

I flattened the prongs down all around, only stabbing myself several times, and it was a nice, secure fit with no need for more zip-ties.

The foam pads are too much for the seat back and you can see the square edges, but other than that, it is very firm and comfortable! The high density foam would have looked even worse. I’m glad that I remembered I had those low density green pads laying around for the last year.

Pardon the mess! The housekeeping staff is on a gap year.